Printer Repair Course

Introduction And Repair Of All In One Printers, Printing Technology, Catridge Maintenance, Scanner Technology, Resolution Function Keys And Operating Menu, Working Of Different Sections Of All In One Printer. Types Of Inkjet Printer, Thermal Process, Print Head, Different Sections Of Inkjet, Motor Sensor, Caping Locking, Wiping, Splitting, Mechanism Of Inkjet Printer & Detail. Function, Block Diagram Of Laser Printer And Its Process, Image Formation(Cleaning To Fusing Process),Electronic Section Of Laser Printer( Formater PCA And DC Controller), Mechanical Section Of Laser Printer( Paper Feeding , Motor Solenoid), Fault Finding Of Laser Printer, Refilling.

Printer Repair Course In Kathmandu

- Introduction To Printers & Types (Laser, Inkjet & Dot-Matrix & Multifunction)

- Printing Principle And Theory Of Different Printers

- Introduction To Different Types Of Ink (Powder, Liquid & Ribbon)

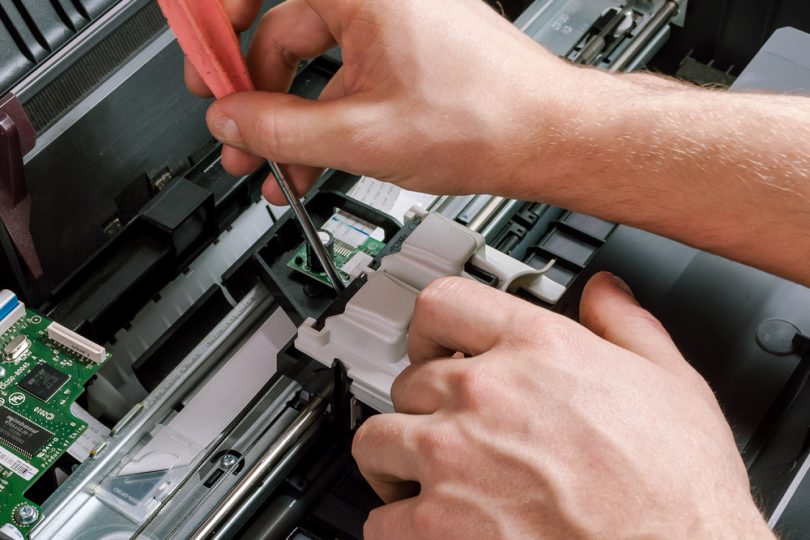

- Assemble And Disassemble Of Different Machines

- Function of laser & H.O.T, SMPS, logic board .

- Working and fixing of components, step motors, sensor, toner, fuser.

Our Printer Repair Course Covers:

Part One: Laser Printer Repair

- Assembly Disassembly.

- Function of laser & H.O.T, SMPS, logic board (partly).

- Special Precautions & Prevention for Laser Printers.

- Working and fixing of components, step motors, sensor, toner, fuser.

- Setting of IP, IO card, ETO / Jet direct, WiFi etc.

- Fault finding, trouble shooting. Alignment of Laser Printer.

- Code identification, error code solving.

- Printer configuration setting etc..

- Testing of Laser toner cartridge and tools.

- Testing of cartridge. Service level setting

- Cartridge Section (Drum, PCR, Badge, Wastage Section, Toner Hopper, Gear, Fuse, Cleaning Roller & Corona Wire)

- Refilling Process Of Different Cartridge (Canon, HP, Samsung & Brother And Inkjet) Ribbon Change Process Of Dot-Matrix Printe

- Gear Section (Motor, Belt, Main Gear, Sub Gear & Relay Switch

- Fuser Section (Heating Roller, Heater, Teflon Paper, Sensor

- Laser Section(Board, Motor, Lens & Mirror)

- Power Supply Section (SMPS & Logic Board)

- Different Sensors, Switch, Pickup Roller, Exit Roller)

Part Two: Inkjet Printer Repair

- Introduction of Inkjet.

- Assembly Disassembly.

- Testing of cartridge

- Manually cleaning of head using chemical.

- Fault finding, trouble shooting.

- Replacing trailing cable.

- Working and fixing of components.

- Service level setting.

- Ink Section

- Board Section

- Head Section And Head Cleaning Process

- Power Supply Section (SMPS & Logic Board)

Part Three: Dot-Matrix Printer Repair

- Assembly Disassembly.

- Gear assembly setting.

- Fault finding,

- Logic board(partly).

- Paper sensor.

- Tractor assembly.

- Service manual reading.

- Driver installation.

- Working and fixing of components.

- Setting of IP, IO card, ETO / Jet direct, WiFi etc.

- Head Section (Head, Head Mask, Head Carriage, Head Cable)

- Ribbon Section (Motor, Gear, Belt, Sensor, Roller & Bush)

- Front Section (Front Panel, Buttons, Lever)

- Power Supply Section (SMPS & Logic Board)

Part Four: Cartridge Related Problem:

- Paper Jam

- Light Print

- Blank Print

- Half Paper Print

- Overlapping

- Vertical Line, Horizontal Line

- Paper Tear, White Print

- Dots On Paper

Part Six: Machine Related

- Paper Dry,

- Paper Not Sensing,

- Jam Inside, Paper Tear)

Part Seven: Multifunction Machine Related (3 In 1, 4 In 1 And Wireless)

- Reset Of Different Machines

- Software Installation

- Firmware Upgrade

- Driver Installation And Download

- Cartridge Reset

- Troubleshooting And Problems Findings In Detailed (More Than 100 Errors)

Course Duration: Regular Course-45 Days & Short Course-15 Days

Training Time: 2 Hours Per day(Theory 20% + Practical 80%)

Language of instruction:Nepali/Hindi/English

Eligibility Criteria: 8 to 10th Class(At Least Completed Grade 8)

Group structure: 6 Participants Per Group

New classes starts on: 1st,10th and 20th(Every Month)