Fridge Repair Training in Kathmandu

Universal Electronics Institute, located in Kathmandu Nepal, presents comprehensive courses in Refrigeration-fridge as well as Heating, Ventilating, and cooling. Our specialized programs equip students with cutting-edge knowledge and hands-on skills, empowering them to excel in the dynamic field of climate control technology. Through expert instruction and practical training, students gain a deep understanding of refrigeration systems, principles, cooling techniques, and ventilation technologies.

Almost every household in Nepal uses a refrigerator (Fridge). Even big size refrigerators are used for commercial purposes. But all of us must have experienced that when such a useful appliance stops working, food gets stale, and many of us know how difficult it gets to deal with frosting. To overcome such situations and to be able to make the best use of skills like repairing refrigerators, Universal has brought a complete course on how you too can start your service agency by getting the skill of repairing the refrigerator(Fridge) can be done. Get to learn every technical detail of how you can repair a refrigerator and earn a good profit out of this service-based business.

This refrigeration (Fridge) repair training course at Universal Institute will expand your knowledge of refrigeration Basics to the very advanced concepts and the industry best practices. The course explains how theory is applied within the industry, gives complimentary preparation to practical training, and offers an insight into the industry’s best practice. It is beneficial for anyone planning for a career in HAVC industry,. Beginners, and refrigeration (Fridge) engineers keen on keeping up to date and re-skilling. The Refrigeration training course series is intended for users who want to improve or acquire knowledge and skills in air refrigeration servicing. You will learn how theoretical principles and knowledge of concepts that are applied within the refrigeration industry.

We have a group of experienced and knowledgeable faculties who have years of hands-on experience of Fridge refrigeration repairing. They ensure recognizing your talent and put their best to make the most out of it through continuous improvement.

Fridge Training in Kathmandu

A fridge is among the most important household appliances since it keeps your food fresh for a long time. Even a minor defect in its functioning might make your food go bad. Regular clean-up and maintenance will prevent the occurrence of any problem in the functioning of your Fridge. You might, however, get stuck with a defect in your fridge and need to address it immediately. In such a case, a Fridge repair company can take care of the matter rather quickly.

A fridge certification programs, live training classes’ expert trainer. We provide 100% practical training and job placement, 15+ year industrial expert trainer. Job-oriented course. Brands: 100+ batches completed, 100% student satisfied, up to 40 client site visit, each day live session, free tool kit provide.

Hands-On Training: Get your hands dirty and gain 100% practical experience with state-of-the-art equipment.

Expert Instructors: Learn from industry professional with 23 +years of real-world experience.

Career Opportunities: Open the doors to exciting career opportunities in HVAC systems and climate control.

Best Fridge Repair Training Center in Nepal

This fridge Repair course provides the basic information and skills related to servicing, repairing and executing other maintenance tasks on latest and modern domestic refrigerators. As Fridge Repair become more advanced, the world has seen a growing need for refrigeration experts. This is because, today’s fridge are expected to provide multiple utilities. From cooling food to preserving it for a longer period and also repelling insects, a fridge does a lot more today that it used to.

This means that there is a need for updated skills in the field of fridge repair and maintenance. Mechanic one has various job opportunities in government as well as private sectors, one can even start his own business. Then you are at the right place. Here, we are providing a detailed description like Basic to Diploma fridge Rearing Course qualification, duration, eligibility, fees, syllabus, career, and more.

After the completion of this course, you have an opportunity to work full-time or part-time in a fridge repair mechanic place. Thus, with the proper knowledge of the fridge mechanism, you will also be able to get a sound salary.

Freezer Repairing Course

The freezer Training Course is a complete reference on the topic. The Refrigeration Cycle Basics are covered step-by-step, to give a complete understanding on the Refrigerator Working Principle. Basics like molecular change due to Sensible & Latent heat variation, Temperature and Pressure are covered intricately. Mollies diagrams and Psychometric charts are explained in explicit detail with animated description of the changes of state.

Freezer Training Course is the only skill that you can learn fast and start earning as quickly as possible. There are many companies that provide freezer Training leads in all cities and towns across Nepal.

The Freezer Training skill is always in demand because it’s an essential service, and it will never die or fail in the future.

Then, go ahead and acquire this skill that gives you the freedom of work and the money that you deserve.

- Full repair course

- Complete notes

- Government and private certificates

- Easy Loan from government

- 100% placement in top companies

Deep Fridge Repair Training

We provide all types of deep freezer repair training services, non-frost fridge, deep-frost fridge, and double-door fridge. This course was absolutely fantastic and full of invaluable information. The information taught in this course has helped demystify the technology used with A to Z Refrigerators / Freezers and has given me more confidence to start working on troubleshooting these units on my own.

Learn an easy, foolproof approach to troubleshooting and fixing every system in every fridge, from classic sealed systems to today’s PCB-controlled contraptions. Train to be a master fridge repair technician and start making bank.

Our Mission

Provide comprehensive training that is both accessible and affordable to help technicians master their trade and support a to z fridge repair owners as they build more profitable businesses.

Why to learn?

Refrigerator knowledge is a mandatory requirement for one who plans to buildings, Food industries, Power stations, Hospitals, Hyper malls, Pharmaceutical industries, Agricultural industries, Airports, Automobiles industries, Aeronautical Plants, Polymer industries, and many more. This course is aimed at students who are interested to build a career in Refrigerator repairing Field. Training Provides In-depth knowledge in Mechanical, electrical, Refrigerator Technology.

Course Syllabus

Week-1: Refrigerator (fridge) Technology

Gain in-depth knowledge of how fridge operate by learning the systems, components, and operational principles.

Week-2: Aircraft Refrigeration Cycles, Vapor Compression Cycle, Actual vapor Compression

Week-3: Common Problems and Troubleshooting

Learn our systems-based approach to fixing everything from warm compartments to frost buildup.

Week- 4: Sealed System Diagnostics and Repair

Break through the mystery of sealed system operation, troubleshooting and repair.

Week-5: Human Physiology, Thermal Comfort, Indoor Environmental Health, Problem Solving

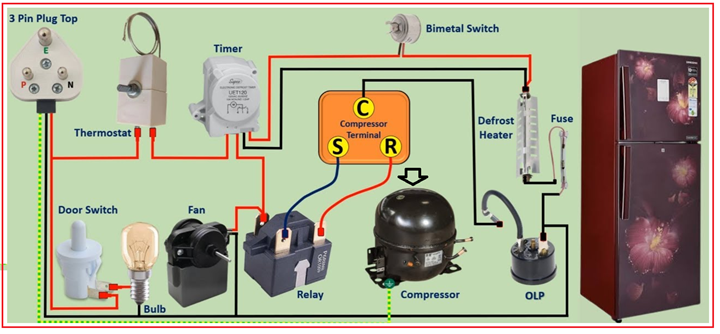

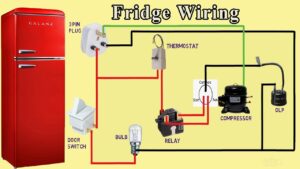

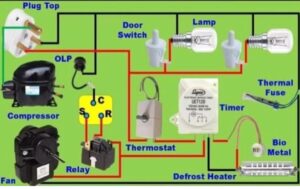

Parts of fridge: There are several Parts of the inside of fridge that work together to ensure the proper functioning of the Refrigerator fridge. Compressor, Evapoter (Cooling Box), Dryer, Capillary, Accumulator, Thermostat, Bio-metal, OLP- Over load protector, PTC Relay, Timer, Fan, Heater, Thermal Fuse, Door Switch, Bulb holder

How much does fridge training cost and duration in Nepal?

Fridge Repair Course Fee and Duration

| Course Tittle | Timing | Duration |

| 1.Regular Course | 1.5 Hour | 45 Days |

| 2.Crash Course | 3 Hour | 25 Days |

| 3.Fasttrack Course | Full Day | 7-10 Days |

Fridge training course fees

The Fridge training course fee may vary from one institute to another. The course duration ranges from 1.5 months. Total course fees ranges from NRs. 15,500/- depending upon the combination of courses selected & can be paid on installment basis. Similarly the duration of course selected can be customized as per the need of the student.

Fridge Parts Name List and Their Function

There are several Parts of the inside of Fridge that work together to ensure the proper functioning of the refrigerator.

1. Types of refrigerator

(Home & Business propose-French door Refrigerators, Side-by-side refrigerators, Top freezer refrigerators, Bottom freezer refrigerators, Under counter refrigerators…)

2. Brands of Refrigerators in Nepal

(Whirlpool, LG, Samsung, Hitachi, Toshiba, Panasonic, Hisense, Videocone….. etc.)

3. Current(AC/DC) and Earthing

4. Ampere,Watt and Resistance

5. Degree Fahrenheit and Degree Celsius

6. Measuring Volume of Refrigerator in liter

7. Refrigerator Accessories:

(Magnetic Gasket, Door, Handel, Ice Cube tray, Door key, Crisper, Crisper cover glass, Guard rail, etc.)

8. Parts of refrigerator:

Compressor, Evapoter (Cooling Box), Dryer, Capillary, Accumulator, Thermostat, Bio-metal, OLP- Over load protector, PTC Relay, Timer, Fan, Heater, Thermal Fuse, Door Switch, Bulb holder.

9. Testing of parts by Multimeter

(Compressor, Thermal Fuse, Bio-metal, Wire, Thermostat, Heater, Timer, OLP, Relay, Fan motor, PCB Board components. )

10. Ammonia Gas

(R22, R134A, R410A, R600A, R32, R290, R407C, R404A, R417)

11. Control Board

(Display Panel Board, Inverted Board, Power supply Board)

12. Refrigerator repairing Tools:

(Clamp Multi meter, Tube Pipe Cutter, Tube Pipe Bender, Gauges (Pressure and compound), Hose Pipe, Vacuum Pump, Spanner Set (8mm to 32mm), Nose pliers, Hammer, Flaring and swaging tools, Adjustable wrench, Allen Key, Flat File, Measuring Tape, Hack Saw, Pliers, Flammable Gas (L.P.G), Gas leakage tester, welding gun with regulator, soldering iron(paste and solder), Soap and foam, Torch light, lighter, Demoisturizer tools, Manifold valve, Screw driver, etc)

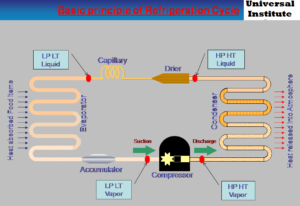

13. Refrigerator Cooling System Block Diagram

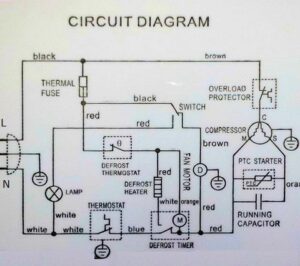

14. Wiring Diagram of Refrigerator System

15. Defrost System(Full Automatic, Manually, Using Hot Gas

16. Practice of cooling system (Practically)

17. Practice of Wiring System of Refrigerator (Practically)

18. Troubleshoot of Refrigerator(Cooling system, Defrost system and Wiring system)

Refrigerator Parts Name List and Their Function

There are several Parts of the inside of fridge that work together to ensure the proper functioning of the Refrigerator.

1. Compressor

The refrigerator compressor is one of the four main components that makes the refrigerator work. The compressor’s job is to compress and control the flow of refrigerant. The compressor receives low pressure gas from the evaporator and converts it into high pressure gas. As the gas is compressed and the pressure increases, the temperature increases.

2. Condenser

A refrigerator condenser is one of the main operating components that make up the cooling system on a standard refrigerator. It consists of a series of copper tubes that overlap in a grid or coiling pattern. On most models, the condenser is located at the back of the unit, though some may be installed on the bottom or along one side of the unit. While its size can vary, it often covers at least half of the area of the refrigerator wall, and some even cover the entire wall of the unit.

3. Dryer

A filter-drier in a refrigeration or air conditioning system has two essential functions: one, to adsorb system contaminants, such as water, which can create acids, and two, to provide physical filtration. Evaluation of each factor is necessary to ensure proper and economical drier design.

4. Capillary tube

Capillary tube is one of the most commonly used throttling devices in the refrigeration and the air conditioning systems. The capillary tube is a copper tube of very small internal diameter. Capillary tube used as the throttling device in the domestic refrigerators, deep freezers, water coolers and air conditioners. The capillary tube will control the refrigerant flow by the pressure drop across it in a refrigeration system. The diameter and length of the tube would determine the flow at a given pressure. It won’t maintain evaporator pressure or superheat. It doesn’t have any moving parts so there is no wear out.

5. Accumulator

The accumulator is a protective device that captures and aids to change the state of the refrigerant from a liquid to a gas. The accumulator can also capture and redirect refrigerant oil that travels throughout the refrigerant circuit. So, in short, the accumulator is present to protect the compressor.

The accumulator has different roles: To provide compressor protection, preventing compressor failure due to liquid slugging. To retain moisture and contaminants from the system (during the accumulator’s lifetime) To ensure oil return and ensure that only refrigerant is returning to the compressor.

6. Evaporator(Cooling Box)

The evaporator is located inside a refrigerator and is the part that makes the items in the refrigerator cold. As the refrigerant turns from a liquid into a gas through evaporation, it cools the area around it, producing the proper environment for storing food. The evaporator works the opposite of the condenser, here refrigerant liquid is converted to gas, absorbing heat from the air in the compartment. When the liquid refrigerant reaches the evaporator its pressure has been reduced, dissipating its heat content and making it much cooler than the fan air flowing around it.

7. Thermostat

Thermostats are typically found inside the refrigerator and have a knob that allows users to adjust the temperature setting. Once a user sets the desired temperature, the thermostat maintains that temperature by controlling the flow of electricity to the compressor. If the thermostat is the brain, the compressor is the heart of the operation, responsible for pumping the refrigerant through the coils.

When the air inside the refrigerator is at the desired temperature, the thermostat stops the flow of electricity to the compressor. When the thermostat senses too much heat, it allows electricity to flow, activating the compressor.

8. Bimetal disc

An electrically isolated bimetal disc is used to either open or close the circuit current. and any double door refrigerator support this Bimetal Applications – Refrigerator – Electrical Blanket – Showcase – Ice Machine – Electrical Stove etc. It stops the fridge from overheating during the defrost cycle by protecting the evaporator.

9. OLP- Over load protector

The overload protector is a small piece that provides a valuable service for any appliance that uses a compressor, such as a refrigerator or air conditioner. An overload protector is an electrical device that we use for compressor protection, whenever the compressor temperature high from his range the compressor overload cuts off the electric supply from the compressor motor that’s why we called him thermal overload.

10. PTC relay

A PTC relay means positive temperature coefficient is a starting device for refrigerator compressors. It is responsible for providing power to the start winding for a brief moment to help start the cooling compressor motor.

11. Defrost Timers

Defrost timers are used to shut off the refrigerator compressor and the evaporator fan motors. They turn on the defrost system at regular intervals to rid the evaporator of defrost. Over time, the timer motor, motor bearing, or reduction gears on electromechanical timers can wear out. It acts like a clock by switching between activating the cooling cycle and the defrost heater to maintain the set thermostat temperature, preventing the unit from being too warm or cold. The defrost timer may need to be replaced if the fridge will not maintain its temperature or has frost buildup.

12. Colling fan

The fan runs whenever the compressor runs, and it draws cool room air through the front grille, and circulates it through the condenser coils, over the compressor, and back out the front grille into the room. The circulating air helps cool the compressor and the refrigerant in the condenser coils.

13. Heater

Every six hours or so, the timer turns on the heating coil. The heating coil is wrapped among the freezer coils. The heater melts the ice off the coils. When all of the ice is gone, the temperature sensor senses the temperature rising above 32 degrees F (0 degrees C) and turns off the heater.

14. Thermal fuse

To prevent overheating, thermal fuse will be blow when the temperature reached to 76 °C inside the evaporator section. If the thermal fuse blow off, the refrigerator will stop all the functions(the compressor will not run and the defrost heaters will not heat).

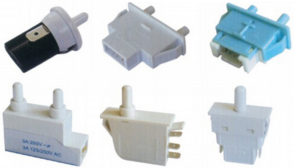

15. Door switch

It is activated when the door closes on it, so it will be visible with the door open. It will be located somewhere along the internal frame of the refrigerator. Once you have located the door switch, remove it. There may be a single screw retaining the door switch inside its housing Switch.

16. Bulb holder & Bulb

Refrigerator: Usually takes a 25- to 40-watt standard base appliance bulb, but some refrigerators use a T8 intermediate base bulb. The benefit of having a light inside either compartment is that it becomes easier to find things. Since most people open the refrigerator far more often than the freezer, the benefit of having a light in the refrigerator is considerably larger..

How does a Refrigerator work?

Refrigerators work by causing the refrigerant circulating inside them to change from a liquid into a gas. This process, called evaporation, cools the surrounding area and produces the desired effect. You can test this process for yourself by taking some alcohol and putting a drop or two on your skin. As it evaporates, you should feel a chilling sensation – the same basic principle gives us safe food storage.

To start the evaporation process and change the refrigerant from liquid to gas, the pressure on the refrigerant needs to be reduced through an outlet called the capillary tube. The effect is similar to what happens when you use an aerosol product such as hair spray. The contents of an aerosol can is the pressure/liquid side, the outlet is the capillary tube, and the open space is the evaporator. When you release the contents into the lower pressure open space, it turns from a liquid to a gas.

To keep a refrigerator running, you need to be able to get the gaseous refrigerant back to its liquid state, so the gas needs to be compressed to a higher pressure and temperature again. This is where the compressor comes in. As mentioned earlier, the compressor provides a similar effect to that of a bike pump. You can sense the heat increase in the pump while you pump and compress the air.

Once the compressor has done its work, the gas should be under high pressure and hot. It needs to be cooled in the condenser, which is mounted on the back of the refrigerator, so its contents can be cooled by the ambient air. When the gas cools off inside the condenser (still under high pressure), it changes back into a liquid.

Reading wiring diagrams : How the Defrost Cycle works in a refrigerator. Service on the refrigerator should be performed by a qualified technician. A wiring diagram is a drawing of the electrical circuit of whatever it is you are working on. On this page I will explain the basics (singal and dobble door) on how to read a diagram.

Dobble door fridge wiring diagrams

How to Understanding fridge wiring diagram?

The wiring diagram located on the cabinet back or behind the grille depicts. DO NOT attempt a product repair if you have any doubts as to your ability to complete the repair in a safe and satisfactory. Choose a symptom to see related refrigerator repairs. The overload relay is a protection device used in the compressor circuit on your refrigerator. A domestic refrigerator not only does it have a complicated electrical control. Anybody know where I can find a wiring diagram.

The wiring diagram (mini-manual/schematic) is packaged with each model. The most common locations are listed below:

- Behind the front grill (in the center or on the left side).

- The left or right side by the condenser.

- Inside the refrigerator section in the control panel.

About Fridge Repairing PDF book

If there is complete guide-book on air conditioner repair ever known, then this book is the one and only complete guide-book for air conditioner repair in English language. If you are seeking for a way by which you could exchange personal services for money, then this book will be perfect for you. This book is for the young people, students or anyone who is seeking for a good resource for practical learning towards self reliance. Through the pages of this book, a reader will be trained to become a great ac repair technician with a brighter and faster earning potential than most ac technicians. The book ends with a chapter of information on how to set up a shop and efficiently managing a air conditioner repair services support center and all about repair tools . Click here for download